Project Cadence

A semi-ongoing side project to develop a running shoe with purity of purpose.

Everyone said we were insane to try this. We proved them right.

CW/shoe designer/ shoe tester/ pattern maker/ vendor relations/midsole designer/ insole board maker/ sweatshop intern: Patrick Lapera

AD/Shoe designer/ Brand designer/ sweatshop intern/ pattern master/ prototyping/product photography: Colin O’Shea

AD/Shoe designer/ Brand designer/ sweatshop intern/ logo designer/ prototyping/ product photography: Katie Paxton

Prototype version 2. Available in any color you want, as long as it’s International Orange

project cadence

Distance runners build their lives around their training cycles, the months long training regimens that prepare runners for events like the marathon.

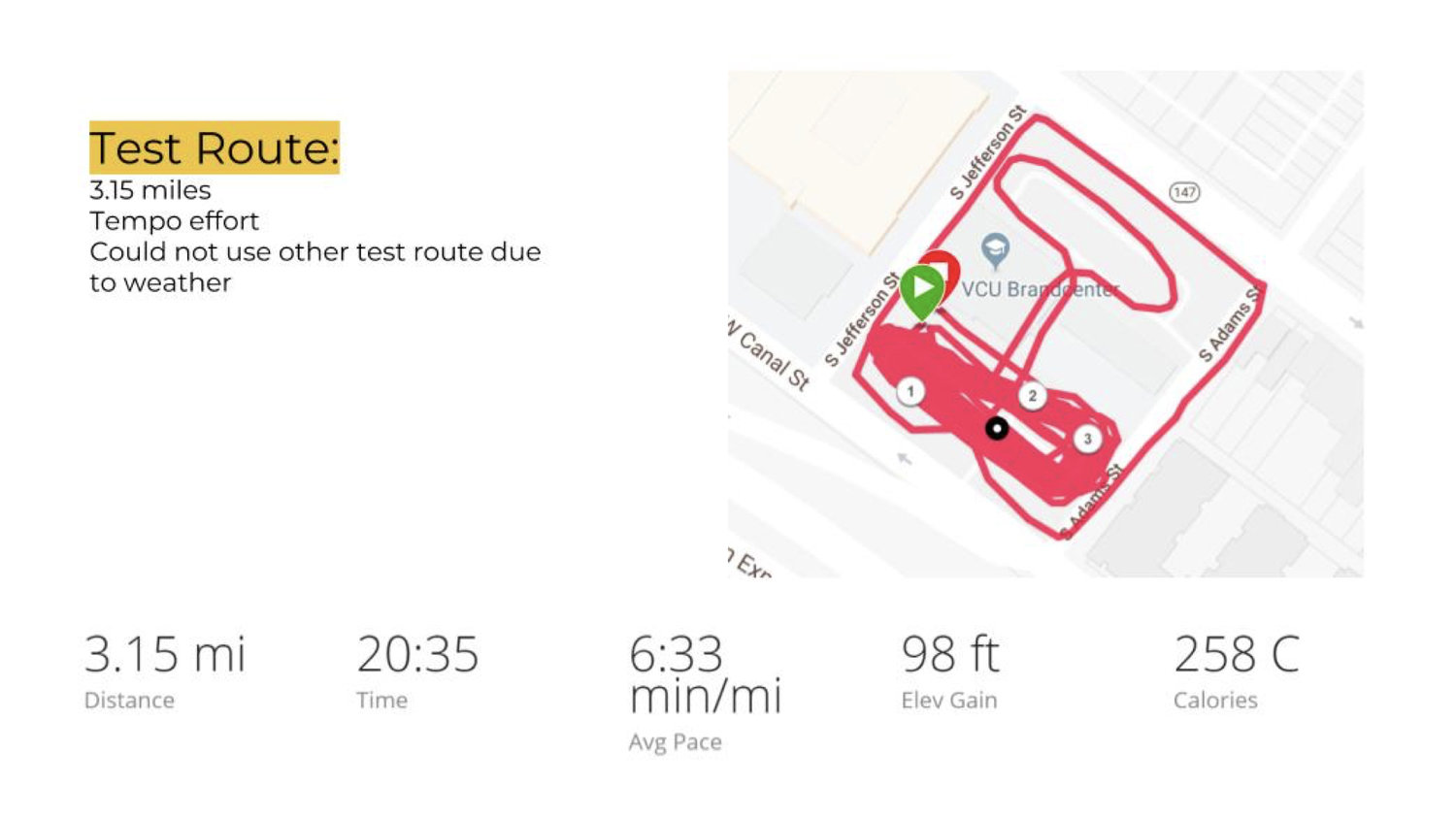

Those training cycles are built around tempo runs and long runs. Long runs build stamina. Tempo runs are runs at race pace which build speed. While these runs comprise only a small part of a runner’s training, they are the runs which define runners.

There’s one problem -- nobody builds running shoes around these training cycles.

Project Cadence aims to change that.

Prototypes 1 and 2 next to each other. You’ll never guess which is which!

faster and more sustainable

Our tempo shoe lasts the 16-18 tempo runs of a training cycle, after which it’s sent back to be resoled. By trading durability for re-usability we’re able to make the shoe both faster, more protective, and more sustainable.

Our prototypes the weight conscious design of a racing flat with new advances in shoe technology. When the shoes wear out all that has to be replaced is the thin rubber outsole -- which can be recycled.

existing tech used more intelligently

We’ve swapped the traditional EVA midsole with a faster and springier ETPU midsole that doesn’t lose its bounce over time. 3d printed carbon fiber shanks and heel counters mean our shoes don’t lose their ride over time, and a 4d knit upper creates no waste during the manufacturing process.